Plastics Technology

-

Plastics Technology

Development of large-part low-pressure injection molding started with the structural foam process decades ago and evolved. Counter pressure and co-injection were early adaptations to improve surface finish. Gas assisted injection molding emerged as a method to produce large thin walled pieces with thicker structural ribs. The latest addition to the website is a collection of…

-

About Steve Ham

Who is Steve Ham? Product DevelopmentMarketing Plan/Sales ImplementationStructural Plastics Process EnhancementSeminars and Workshops on Various Structural Plastics Technologies Structural Plastic and Continuous Improvement Production programs which suffer from problems will affect timing and degree of profit. Problem identification is essential in determining the cost and timing for various remedies. Good decisions can only be made…

-

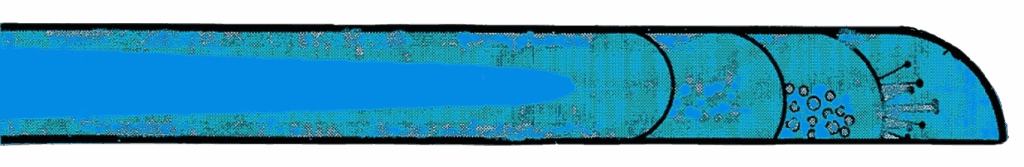

Water Assisted Injection Molding

This fascinating technology isn’t right for every application. Here is a link to the story: WAM is up and running – Molding 2004 B

-

Best of the Structural Plastics Conferences 1974-2002

A selection of technical papers and applications from the Society of the Plastics Industries’ annual technical conferences 1974-2002. Over this thirty year period, the annual conference generated 727 white papers and displayed thousands of new applications. Here are some samples of the best of the best. We start with several design oriented papers: The following…

-

Comparing the Various Structural Plastics Processes

Nitrogen assisted alternatives to high pressure injection molding of large pieces are explored- Structural Foam, Counterpressure, Gas Assist, and External Gas Molding. Plastic flow and resin shrinkage are considered. There is something about bubbles of nitrogen gas in molded plastic that assists with the process. Nitrogen gas is really a choice of convenience since it…

-

Cashiers Plastic Corporation

Cashiers Plastic was a leading custom molding manufacturer from 1969 to 2006. Located in an unlikely resort town in the Blue Ridge Mountains, it provided a unique background for excellence. One Man’s Vision- Fifty Years On This is a story about the Cashiers community and how one man’s vision created opportunity for a whole generation…

-

External Gas Molding

External gas molding represents the latest advanced method of injection molding thin walled parts with large surface areas. The process involves the injection of a blanket of gas assist to one surface of the molded part to compensate for shrinkage on the other surface. Resin shrinkage is the cause of molded in stress, sink marks,…

-

EGM White Paper

Measuring In-Mold Pressures with the External Gas Molding Process (2006) Jim Hendry, Brian Brookshaw, and Kamal Vinning – Cinpres Gas Injection Steve Ham – Steve Ham Plastics Abstract External Gas Molding (EGM) is an emerging new method of injection molding. One of the main claims of the process is drastically reduced packing pressures allowing low…

-

Design for Function (White Paper)

STRUCTURAL PLASTICS- DESIGN FOR FUNCTION Steve HamSteve Ham Plastics, Highlands, North Carolina Abstract A methodology in producing highly functional designs is discussed. The family of injection molding processes referred to as Structural Plastics offers product designers more design liberty with net-shape moldings. The inherent high cost of “plastics” is offset with highly functional and value…

-

Structural Foam

Structural Foam molding has been around since the sixties but remains unknown to many product designers. It is a way to injection mold very large parts. Traditional thermoplastic resins are used along with a blowing agent which produces a molded article with a cellular core and solid skins. These Polyethylene water tanks convey the concept…