Steve Ham shares his specialized knowledge gained during a career that started in 1973.

This website was first published in 2000, making basic PLASTIC DESIGN reference material available at no cost. The material may be reproduced with proper credit. Steve Ham spent forty years in industry utilizing advanced injection molding processes.

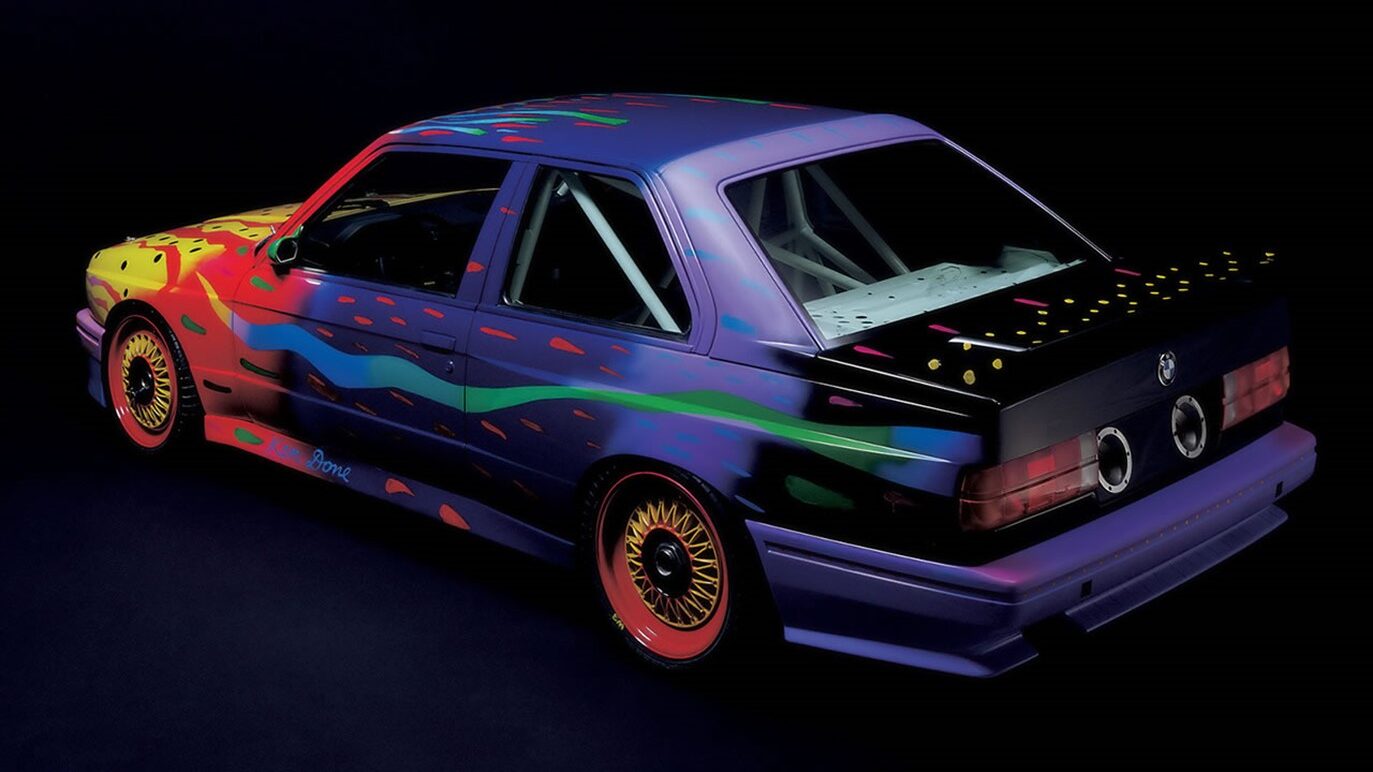

The remainer of this website is devoted to Steve’s other interests. You are welcome to explore car stories, antique clocks, aviation history and more from the “Amazing” and “Special Cars” category tabs. Enjoy………

Contact Steve at 828 526 0598 or steveham@dnet.net