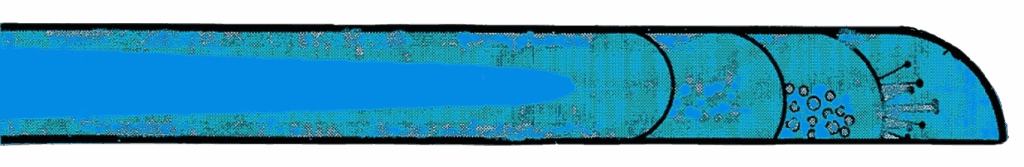

Counterpressure Structural Foam is a variation of the structural foam process. The purpose is to control the pressure drop at the leading edge that occurs during resin injection. Normally the pressure drop allows the blowing agent to expand during mold filling causing a visual defect called “swirl”.

The Counterpressure in the mold cavity controls blowing agent expansion at the leading edge of the flow front. Nitrogen gas pre-pressurizes the mold cavity prior to plastic injection. Controlled venting and a pressure tight mold are essential elements of the process.

Counterpressure actually works well with EGM. Counterpressure is a valuable tool employed during the mold filling phase of the injection molding process. EGM uses the same mold sealing techniques and kicks during the packing or resin shrinkage phase.