Piece part designers must have an understanding of the molding process being employed. Design for function and optimization require that every potential benefit of a given resin/process be exploited. At the same time there are design basics that must be respected. Such details as wall thickness, corner radius, and rib profile require special attention during the design cycle.

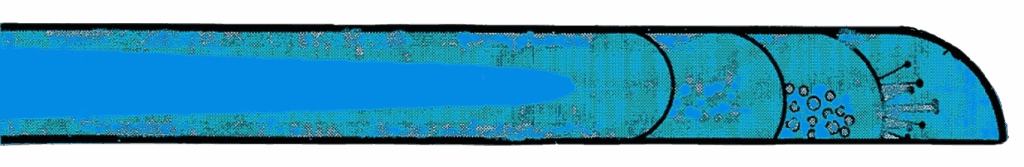

The gas assist process offers an incredible design flexibility. The structural elements are also the processing bonus when the design is properly executed.

Structural Foam is a very forgiving process for the piece part designer. Variations in wall thickness and the option of thick ribs have made this a favorite process for designer’s since the early 1970’s. With today’s competitive environment in so many markets, designers no longer have this option. New designs can be optimized to achieve maximum function at minimum cost. Structural Foam can be optimized to be the most competitive process in many applications. The thicker wall sections can often be offset by using less costly resins.

External Gas Molding (EGM) offers the designer more flexible options of rib design for thin walled parts. Rib profiles of .8 to 2.0 are achievable. Normal injection molding limits rib profile to about .8. Gas assist molding requires a thicker rib of 2.5 to 3 in order to contain the gas bubble. EGM is effective in this middle ground of .8 to 2.0.

More Injection Molding Component Design Basics: https://www.3dhubs.com/guides/injection-molding/#design-for-injection-molding