Plastics Technology

-

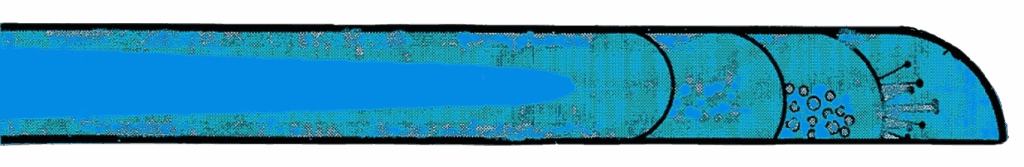

Gas Assisted Injection Molding

Gas Assisted Injection Molding was one of the fastest growing new injection molding technologies in the 1990’s. And yet, less than 20% of all currently active injection molding machines are equipped with this feature. Here’s how Short Shot Gas Assist works: In the initial phase, the resin is injected into the empty mold cavity. The…

-

Design Guidelines

Piece part designers must have an understanding of the molding process being employed. Design for function and optimization require that every potential benefit of a given resin/process be exploited. At the same time there are design basics that must be respected. Such details as wall thickness, corner radius, and rib profile require special attention during…

-

Counterpressure Structural Foam

Counterpressure Structural Foam is a variation of the structural foam process. The purpose is to control the pressure drop at the leading edge that occurs during resin injection. Normally the pressure drop allows the blowing agent to expand during mold filling causing a visual defect called “swirl”. The Counterpressure in the mold cavity controls blowing…