Structural Foam molding has been around since the sixties but remains unknown to many product designers. It is a way to injection mold very large parts. Traditional thermoplastic resins are used along with a blowing agent which produces a molded article with a cellular core and solid skins. These Polyethylene water tanks convey the concept of size capability:

The following sequence illustrates how the process works:

Prior to resin injection, the mold is clamped with 1/4 ton per square inch minimum clamping pressure. The pre-blended material is held in the machine in an accumulator prior to injection.

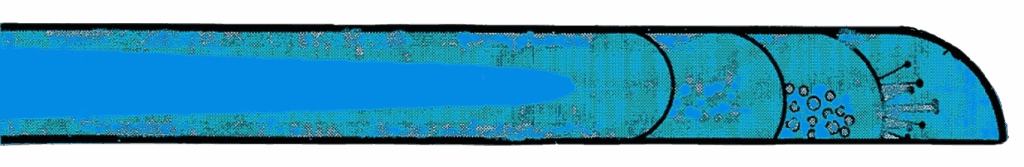

The machine injects a precisely measured short shot of material. Structural Foam’s thicker wall section along with the blowing agent boost allows rapid and low pressure filling.

After resin injection is completed, the cavity pressure is isolated and the blowing agent pressure continues to fill the mold cavity.

The blowing agent pressure continues to pack the mold even after the mold cavity is completely filled. This blowing agent pressure compensates for volumetric shrinkage as the plastic cools. The blowing agent becomes an internal “cushion”.

Structural Foam molded as a low pressure short shot will exhibit “Swirl” or flow marks on the surface of the molded part. This natural occurrence results from the pressure drop on the leading edge of resin flow front during the mold filling phase of the process.